Description

Meet One of Our Most Popular and Versatile Lifts

A four-post lift requires a serious level of engineering. To reduce strain on the columns and provide ample lifting security at all times, BendPak uses the most durable stainless steel lifting cables, as well as the single hydraulic cylinder, to provide an incredibly powerful and smooth lift operation. With proper use, this car lift will work as well in 10 years as it did on day one.

The HD-9 offers our largest variety in any BendPak four-post lift weight class because most vehicles serviced by most shops weigh less than 9,000 lbs. If you need to lift heavier vehicles, we have larger-capacity models that keep you covered. For many of you, however, the HD-9 Series will hit the sweet spot for powerful lifting, compact design and product value. Browse our 9K section to see all of what you can get on these models.

Dual-hub cable sheaves

Dual-hub cable sheaves are more expensive to manufacture, but we’d rather send you home with a quality product than a cheap one. They’re necessary to prevent axles, sheaves and cables from burning out before they should. Our philosophy is that your lift should be the last thing you worry about first thing in the morning.

Multi-level locking positions

Unique service technicians require unique servicing positions; with the HD-9, you can safely lock your four-post lift at varied heights, so you’re never crouching or reaching uncomfortably to perform auto maintenance. If you’re raising the lift for parking purposes, that variation is going to come in handy, depending on how you stack your vehicles.

Heavy-duty aircraft cable

Each four-post lift comes with four lifting cables made from superior-grade stainless steel. Each individual cable is rated to handle 14,400 lbs. This makes their combined rating over 640% of the total capacity. These cables are hidden within the post columns for both the safety and overall streamlined look of the lift. No one wants to see a cable dangling on the outside of a lift. Tuck that thing away!

Electric-hydraulic power system

No need to worry about maintenance on your electric-hydraulic power systems! The controls are all within reach, so you can stop, start and reverse your four-post lift on a dime.

Large base plates

10″ x 12″ base plates keep your car lift rooted in place for as long as you own it. Make sure the ground is level and you’re good to go!

Caster kit

Ask us about the 4-piece caster kit that fits all our 9K four-post lifts. They turn your stationary lift into a mobile parking and service station. You can even leave a car on top while you move it!

Integrated design

All lifting cables, airlines, safety latches and sheaves are routed internally throughout the car lift. This is a crucial safety feature that also adds significantly to your lift’s curb appeal! (That is, if you have it visible from the curb.)

Low-deck runways

We keep our four-post runways to a low 4.5″, so low-stance chassis can be comfortably driven onto the lift.

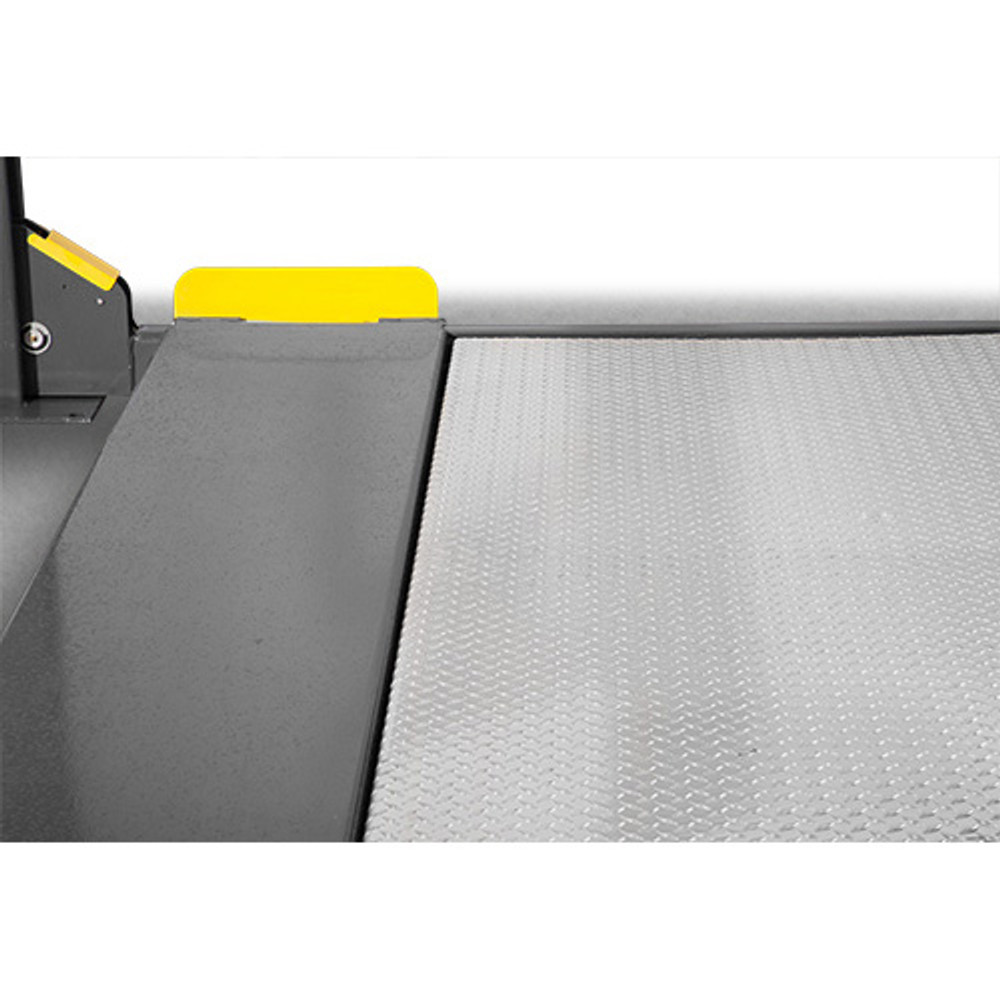

Longer approach ramps

Not only are our runways low, we extend them farther than others in the industry. This better suits the lifting of sports cars and other low-standing vehicles.

Automatic safety locks

Every BendPak four-post lift is designed with a safety-first mentality. To this end, four locks engage simultaneously as the lift is raised, and a backup locking system catches cable slack in the unlikely event of cable failure.

Features & Specs

- 9,000-lb. maximum lifting capacity

- CE Approved and Certified. Meets or exceeds the standards prescribed by European Standard EN-1493

- Freestanding design

- Perfect for parking, storage and service

- Runways accommodate narrow and standard vehicles

- Runways include rail-kit for optional accessories

- Electric / hydraulic power system

- Single hydraulic cylinder mounted underneath runway

- Fully enclosed lifting cables, safety locks and sheaves

- Internal anti-sway slider blocks in each column

- Oversized self-lubricating cable rollers

- Features heavy-duty 3/8″ aircraft cable

- Rugged 1.25″ roller axles

- Multi-position safety locks in each column

- Adjustable lock ladders

- Runways feature non-skid surface

- Push-button pneumatic safety release

- Independent backup slack-cable safety latches

- Customizable power unit location

- Removable approach ramps for additional drive-under clearance

- Longer approach ramps for low-ground clearance vehicles

- Optional drive-thru ramps available

- Optional drip trays available

- Optional solid deck available to increase storage capacity

- Optional 4,500-lb. air / hydraulic rolling jacks available (Model RJ-45)

- ETL Approved

Capacity

Lifting Capacity* 9,000 lbs. (4,082 kg)

*Max Capacity / Front Axle 4,500 lbs. (2,041 kg)

*Max Capacity / Rear Axle 4,500 lbs. (2,041 kg)

Rise

A – Min. Runway Height: 4.5″ (114 mm)

B – Max. Rise: 70″ (1,778 mm)

C – Max. Lifting Height: 74.5″ (1,892 mm)

Time to Full Rise: 45 seconds

Outside Dimensions

D – Overall Width: 110.25″ (2,800 mm)

E – Outside Length: 174″ (4,420 mm)

F – Overall Length: 200″ (5,080 mm)

G – Height of Columns: 88″ (2,235 mm)

Inside Dimensions

H – Width Between Columns: 100.25″ (2,546 mm)

I – Drive-Thru Clearance: 86.5″ (2,197 mm)

Runways

J – Runway Width: 19″ (483 mm)

K – Length of Runways: 164″ (4,166 mm)

L – Width Between Runways: 37.5″ (953 mm) or 44.375″ (1,127 mm)

M – Runway Centerline: 56.5″ (1,435 mm) or 63.375″ (1,610 mm)

N – Outside Edge of Runways: 75.5″ (1,918 mm) or 82.375″ (2,092 mm)

Minimum Wheelbase

Rated Capacity: 115″ (2,921 mm)

75% Capacity: 100″ (2,540 mm)

50% Capacity: 85″ (2,159 mm)

25% Capacity: 70″ (1,778 mm)

Locking

Locking Positions: 12

Lock Spacing: Every 4″ (102 mm)

Power Unit

Motor: 220 VAC / 60 Hz / 1 Ph

Noise: 45 dB

Note: An air supply (minimum: 30 psi / 3 CFM) is required for the safety-lock mechanisms to disengage. It is solely the responsibility of the end-user to provide, install and maintain the air supply.

Note: Not all BendPak lift models meet the standards as prescribed by ANSI/ALI ALCTV-2017 or ANSI/UL 201. Consult www.autolift.org for a complete list or contact BendPak via contact@bendpak.com.

BendPak lifts are supplied with concrete fasteners that meet the criteria of the American National Standard ANSI/ALI ALCTV-(Current). Buyer is responsible for all charges relating to any special regional structural or seismic anchoring requirements specified by any other agencies or codes such as the Uniform Building Code (UBC) or International Building Code (IBC).

Reviews

There are no reviews yet.